Shinji Haneda, Kiryudo

He has served as a chairman of "Zenkoku Obijime Haorihimo Kosei Torihiki Iinkai," or fair trade council of sash bands and Japanese half-coat cords in Japan, a chairman of "Tokyo Kumihimo Itokokai," or Tokyo Kumihimo thread club, and a representative of "Edo Kumihimo Denshokai," or Edo Kumihimo tradition club.

We talked with Shinji Haneda, Edo Kumihimo Kiryudo (Kiryudo Co., Ltd.)

(Interview: February 19, 2018)

About materials of Kumihimo

Q: Where do you obtain silk materials from?

Haneda: We have imported most silk materials from China. We have commissioned domestic companies to make twisted threads for textiles and Kumihimo from the materials. These are twisted threads. (continued in the lower column)

Q: Where do you dye the threads?

In the present, there is no dyehouse in Tokyo, so we have asked dyehouses in Kyoto or have dyed threads ourselves if the amount of threads is not too much. Since there are wastewater problems in these days, we cannot frequently dye threads.

Q: Do you do herb dyeing?

We rarely do herb dyeing. Speaking within the Kumihimo industry, there is very little Kumihimo dyed with natural dyes. Natural dyes are used for special Kumihimo only: For example, Kumihimo that is dedicated to Ise Shrine once every 20 years and one used for restoration of national treasures. The production of dyes is also low, and they are scarcely distributed. Most of the present dyes are chemical dyes in order to avoid fading.

Q: Do you sometimes make Kumihimo that is dedicated to shrines and temples? In that case, do they particularly specify colors and forms?

Although few in number, we occasionally make those Kumihimo products. They sometimes specify patterns and forms. We do not take orders to make over-complicated Kumihimo products, but sometimes make those used in temples and shrines, such as Izumo Taisha Shrine.

Q: How many types and colors of threads are used? Are there basic colors or color combinations?

Most traditional Kumihimo products are made of raw silk (silk threads). An infinite number of colors can be created through a variety of dyeing methods. There is no basic color. There are some styles in which colors and patterns of sash bands are matched to kimono. I think people tend to prefer quiet colors. Since those sash bands are used with Edo-komon kimono, for example, a little bit conservative colors, such as dusky cinnabar like iron rust, are used for many Kumihimo products. Grayish blue is also used. People prefer colors, such as greenish indigo blue.

Q: Do you use different colors according to seasons? Are there colors like gold and silver?

Yes. Of course, such colors are used for textiles that are rolled and stored, including obi. We do not dye gold and silver. We use so-called gold threads (metallic threads). For real gold, we wind thinly cut gold leaves around threads. In these days, we wind pieces of metal around threads, such as polyester fibers.

Q: Are there some types of thicknesses of threads?

There are types of thicknesses. Basically, we have used threads called "Mikoyori Tanshi," in which three threads are twisted into one thread, and "Sansan no Ito," in which three Mikoyori threads are twisted into one thread. In addition, "Futakoyori"or "Soshi," in which two threads are twisted, are also used. (continued in the lower column)

Q: How do you make thicker threads than these ones?

We make thicker threads by using 9 or 12 threads for Tanshi. For textiles, six threads are twisted into one Futakoyori thread.

About the history of Edo/Tokyo Kumihimo

Q: Could you tell me about the history of Edo/Tokyo Kumihimo?

In the Edo Period, local feudal lords went up to Edo for an alternate-year attendance, and had residences in Edo, so there were many samurai warriors in Edo. Since Kumihimo was a requisite as a sword strap for samurai, there were many Kumihimo craftsmen. It is the origin of Edo Kumihimo. The production of Kumihimo continued in the Meiji Period, and flourished as an industry in the Taisho and Showa Periods until World War II. However, the number of people wearing kimono had significantly decreased after the war, and craftsmen and companies that made Kumihimo disappeared, so its production also diminished.

Q: Where did Kumihimo studios exist at that time?

Those studios existed areas around Asakusa. Our store was located beside the river near Asakusabashi Station in the prewar period. It was at the back of Kyugetsu, a doll manufacturer. We opened a store at the present location, and started to sell Kumihimo products about 20 years ago. We were originally from Kiryu, and engaged in Kumihimo production. Since Kiryu was a producing center of silk fabrics, Kumihimo products also thrived there. Kumihimo products could be made from remains of threads used for fabrics as long as they were not high-quality products. However, samurai warriors disappeared in the Meiji Period, and the entire region of Kiryu had gradually declined. Therefore, my family went to Tokyo.

Q: There are still many wholesale businesses in Asakusabashi. Did your store run wholesale business at that time?

We were a manufacturing wholesaler. We had several factories. We did not do retail selling at all, and sold Kumihimo products wholesale to kimono shops. There were many wholesale drapers, so most of Kumihimo products we dealt were related to kimono fabrics, such as a sash band. However, since people began to stop wearing kimono, a demand for sash bands decreased by about one tenth. So we have striven to survive the situation by retailing products.

Q: Do you distribute Kumihimo products to kimono shops and small article stores?

There are some old customers, so we have still distributed Kumihimo to them.

Q: What kind of activities have Kumihimo associations conducted?

There are two associations in Tokyo: "Edo Kumihimo Denshokai" and "Tokyo Kumihimo Itokokai." Their predecessors were cooperatives, called "Oroshi Kyodo Kumiai," or wholesale cooperative, and "Obishime Kyodo Kumiai," or sash band industrial guild, but operations of cooperatives cost a lot, so the cooperatives were dissolved, and became private organizations. Edo Kumihimo Denshokai has recommended traditional craftsmen, and taken on jobs that are related to the Metropolis of Tokyo. Tokyo Kumihimo Itokokai has taken on jobs related to wholesale notices and the Fair Trade Commission.

Q: Do you make all Kumihimo products that you deal in?

Whether Kumihimo products are made by machine or hand, only 20-30% of Kumihimo companies have made Kumihimo products in their companies. In the existing circumstances, 80% of companies have commissioned craftsmen around the country to make Kumihimo. If we get many orders, we cannot meet them, and craftsmen also have areas of specialty.

Q: What are special orders?

There are a variety of orders, such as a strap for a quiver, in which arrows are inserted, and a truncheon strap.

Q: Are there orders for stage properties?

Although few in number, we receive those orders. We were once requested to make Kumihimo used for an opera.

Q: Craftsmen have held workshops at Shitamachi Dento Kogei-kan located near your store. Do you also join the workshops? Do you hold hands-on classes that are open to the public?

We have joined the workshops. For example, we have created opportunities for students on school excursions to make Kumihimo a few times a year. Although this studio only accommodates 5-6 students, they are instructed to make small pieces of Kumihimo. Since many of them are junior high school students, we turn Kumihimo into straps, and present them to the students.

About tools used for works

Q: Could you tell me about tools and threads that you are using?

Tools are divided into two categories: one for making threads and another for braiding threads. This is a stand called Kakudai on which threads are braided. This round stand is called Marudai. And this is Takadai. Braiding methods and completed forms are different depending on each stand. (continued in the right column)

It is a difference of braiding methods, not of sizes. It is not related to sizes.

Q: What kind of units are you using for measuring length and thickness?

Although we had previously used standard shaku as a unit, the shaku-kan system of measurement was banned by the Measurement Law in December 1958, and the metric system is easier and convenient, so we are now using the metric system.

Q: For example, how long is a sash band?

It is about 1.5m, which is so-called "5 shaku." Japanese body builds were smaller in the past, so sash bands were also little bit shorter.

Q: Is there no occasion to use shaku and sun?

Although we are using the metric system, the shaku-kan system has still been used in some tools.

Q: Are there standards for sizes and forms of Kumihimo?

For a tool called "Kaseagedai" that is used for measuring length by winding threads around it, length is measured in shaku, so shaku is converted into metric measurement.

Q: Why do sizes of Kaseagedai differ?

It is a difference of an amount of threads that are wound. We change the sizes according to what we make.

Q: What is a component used for the weight and spool?

It is called "Tama." We have used Tama since olden days, and is measured in momme. One momme is 3.75g, so the lightest Tama is about 75g, and the heaviest is 787.5g. We use heavy Tama when making large pieces of Kumihimo. This is a Japanese half-coat cord for a sumo wrestler, so we are making strong and large Kumihimo using heavy Tama of 210 momme. It needs many times an amount of threads used for a standard cord.

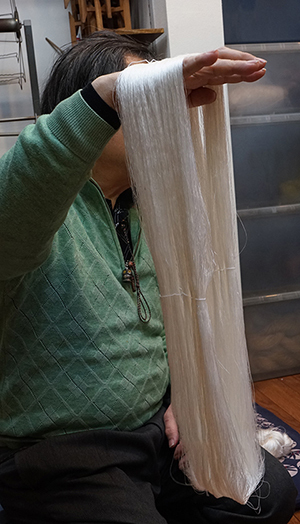

They are used for measuring and cutting threads or for making threads. Also, they are used when drying and organizing dyed threads. (continued in the lower column)

About braiding methods and work processes

Q: What kind of braiding methods are there?

The minimum unit is "Mitsugumi," but there are countless braiding methods. For Kumihimo, there are two systems of braiding: "Mitsugumi" and "Yotsugumi." There are many branches derived from those two systems. For a method called "Sijuhachi," in which an amount of threads used in Yotsugumi is increased, 48 pieces of Tama are used. The greatest number of Tama is used in Mitsugumi that uses a large amount of threads. In some cases, we use about 130 pieces of Tama when making obi.

There is no standard method. A variety of methods and branches have been created. For example, since there were needs to make particular forms of Kumihimo, specific tools were created. Therefore, there are a wide range of Kumihimo products, and we cannot briefly explain it.

Q: It is also possible to make flat Kumihimo like these, isn't it?

Since it has a structure composed of threads, any forms can be created.

Q: For Kumihimo, is there any name of texture like a plain weave in weaving?

Although there are many braiding methods, we basically call them "Kumu," or braiding. Weaving denotes a textile.

Q: Are patterns of Kumihimo created by embroideries? Are there any paper patterns and references?

Those patterns are made by changing threads so that different colors are seen. We scarcely embroider on Kumihimo. Of course, there are paper patterns and references. I am the fifth generation proprietor, and have references that I took over from my father.

Q: Do you think up patterns and designs by yourself?

Since many basic patterns have been handed down, so there are not so many new patterns that I devised. Kumihimo has a long history and traditional techniques, so it is important to observe and hand down them.

Q: Do you bundle multiple threads, and then braid cords?

Processes for making Kumihimo are broadly divided into two processes: One for making cords and another for braiding Kumihimo on Kumidai. Threads wound by round "Kase" of previously-mentioned Kaseagedai are called "Kaseito"...

Q: The first step is to make Kaseito, isn't it?

Although it is on a case-by-case basis, there is a preparatory stage in which threads are dyed, wound, twisted and cut before making cords. We do not have a twisting machine, so we twist threads by hand.

Q: Don't you twist cords when braiding them?

There are many methods. Sometimes we braid cords while twisting them. Basically, we twist cords because it makes Kumihimo more strong and beautiful.

Q: "Sanbon" is made by twisting three single threads, isn't it? Do you make Kumihimo from it?

For Sanbon, single threads are twisted. However, as I mentioned before, there is few companies that produce twisted threads in Tokyo, so we buy twisted threads from a spinning company in Kanagawa Prefecture.

Q: How many threads are used for this cord?

This cord is called "Kyuhon Miko." We buy and dye this cord. This is a process called "Hekiru" or "Heru." "Hekiru" is a term related to textiles, and "Heru," which is in a dictionary, means preliminary arrangements. Threads are twisted in one step in Hekiru. When making a variety of Kumihimo, Hekiru and preparation of threads are carried out differently. When we make this Kumihimo, 32 threads should be bundled, considering the length. We also should not waste threads as much as possible. It can be said that the process for preparing threads is more difficult than that of braiding.

It takes about 10 years for craftsmen to estimate preparations for materials based on thickness and length of Kumihimo. It is not so difficult to just braid it. Since threads should be carefully handled, thread making is difficult.

Q: How much amount of threads is needed to make a standard sash band?

It is about 50g. In the past, we called it like "Juni Mommetsuki" (45g) and "Niju Momme" (75g). The weight varies depending on thickness, but it weighs as much as that in gram. Speaking of the amount, it is greater by about 30% than that of this Kaseito because this Kaseito is 42g.

Q: Do you buy 42g of Kaseito from a spinning company?

Yes, we buy that Kaseito. Although we can buy a variety of Kaseito if we ask thread shops, this amount of threads is needed for a Japanese half-coat cord for a sumo wrestler.

Q: Do you dye raw silk?

Basically, we dye raw silk, but, in some cases, we wrap threads around raw silk and protect a part of it against dyeing depending on patterns. (continued in the next page)

Shinji Haneda, Kiryudo

He has served as a chairman of "Zenkoku Obijime Haorihimo Kosei Torihiki Iinkai," or fair trade council of sash bands and Japanese half-coat cords in Japan, a chairman of "Tokyo Kumihimo Itokokai," or Tokyo Kumihimo thread club, and a representative of "Edo Kumihimo Denshokai," or Edo Kumihimo tradition club.